Unveiling an Extensive Selection of Resilient Undercarriage Parts for Heavy Machinery

Unveiling an Extensive Selection of Resilient Undercarriage Parts for Heavy Machinery

Blog Article

Crucial Overview to Undercarriage Components for Heavy Devices

When it concerns heavy devices, the undercarriage plays a vital function in ensuring smooth and reliable operations. Comprehending the complex information of undercarriage parts is crucial for maximizing the life-span and performance of your machinery. From track chains to idlers and rollers, each part adds to the overall functionality of the tools. Looking into the specifics of sprockets and various other undercarriage components provides indispensable insights right into upkeep methods that can considerably affect the longevity of your hefty equipment. By grasping the importance of these components and their maintenance demands, operators can enhance the performance and resilience of their devices, inevitably leading to set you back savings and enhanced operational efficiency.

Relevance of Undercarriage Parts

Understanding the critical role that undercarriage parts play in the efficiency and long life of heavy devices is vital for efficient upkeep and operation - undercarriage parts. The undercarriage parts develop the structure on which the whole maker operates, sustaining the weight of the equipment, providing security, and absorbing shock lots throughout procedure. A properly maintained undercarriage not just ensures smooth procedure however additionally adds considerably to reducing downtime and repair work costs

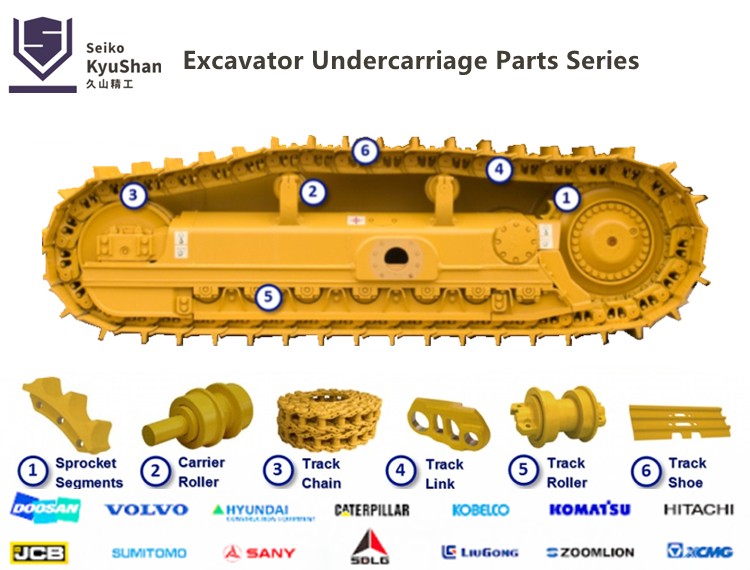

The undercarriage includes numerous important parts such as track chains, track footwear, gears, idlers, rollers, and track structures. Each of these components plays a vital duty in the overall functionality of the tools. The track chains and track footwear aid in supplying grip and assistance, while the sprockets and idlers assist in driving the tracks efficiently. Routine inspection, prompt maintenance, and substitute of worn-out undercarriage components are vital to stop breakdowns and make the most of the life expectancy of the heavy tools. Basically, buying high-quality undercarriage components and guaranteeing their correct treatment is essential for optimal efficiency and sturdiness of hefty equipment.

Kinds of Track Chains

Track chains are necessary components of hefty devices undercarriages, supplying the needed traction and assistance for effective procedure. There are largely 2 kinds of track chains utilized in hefty tools: secured and oiled track chains (SALT) and completely dry track chains.

Function of Rollers and Idlers

Rollers and idlers play a critical role in supporting and directing the track chains of hefty tools undercarriages, adding to the general stability and performance of the machinery. Idlers, on the various other hand, guide the track chain basics and assistance keep appropriate stress throughout the undercarriage system.

With each other, rollers and idlers function in harmony to make sure that the track chain stays in location, even on rough terrain, enhancing the equipment's performance and long life. Proper maintenance and routine inspection of rollers and idlers are important to avoid premature wear and prospective breakdowns, inevitably optimizing the performance and life-span of heavy devices undercarriages.

Understanding Gears

One vital aspect of sprockets is making sure appropriate positioning and tension to avoid premature wear and damage. Misaligned gears can cause irregular wear on the track chain, bring about decreased efficiency and prospective safety risks. Regular Website maintenance and evaluation of gears are important to identify any kind of indicators of wear or imbalance quickly.

Additionally, sprockets come in different sizes and tooth configurations, relying on the particular heavy devices and its desired use. Proper option of gears based upon the tools's specs is important to ensure optimum efficiency and longevity of the undercarriage system. Comprehending the role of gears and their maintenance needs is crucial for taking full advantage of the performance and life-span of heavy devices undercarriages.

Maintenance Tips for Long Life

To ensure the long term resilience and ideal performance of hefty tools undercarriages, diligent upkeep techniques are vital. Frequently evaluating undercarriage components such as track footwear, rollers, idlers, and gears for wear and tear is crucial. Appropriate track stress modification is also crucial for minimizing early wear on undercarriage parts.

Final Thought

In verdict, undercarriage parts are vital components for hefty equipment, playing critical functions in maintaining security and capability. Appropriate care and attention to undercarriage parts are essential to maximizing tools lifespan and productivity.

The undercarriage consists of various essential components such as track chains, track read more shoes, gears, idlers, rollers, and track structures. The track chains and track shoes assist in offering grip and assistance, while the idlers and sprockets assist in driving the tracks smoothly (undercarriage parts). There are primarily 2 kinds of track chains used in heavy tools: sealed and lubricated track chains (SALT) and dry track chains. Correct selection and upkeep of track chains are vital to make certain the total efficiency and longevity of heavy devices undercarriages

Gears are indispensable parts of heavy equipment undercarriages, liable for transferring power from the equipment to the track chain.

Report this page